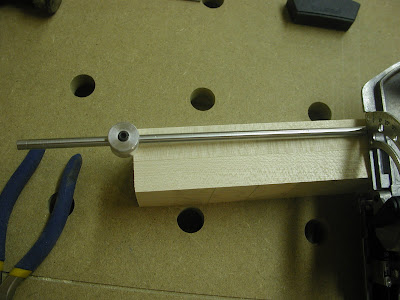

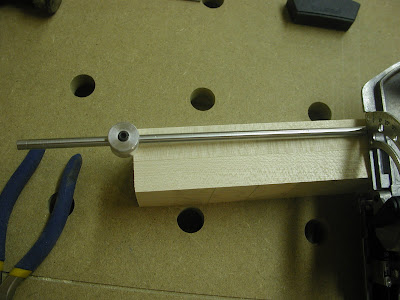

I wanted to put a bolt through the stretchers in order to tighten up an seasonal slack that might occur with this bench. The perfect thing to do, (perfect only because I thought of it,) was to use two dowels for anti-rotation pins and then put a bolt through the stretcher. This is just a short blog entry today.

This video is how I used Dowelmax to align the stretchers to the base.

In part IV of this series, I'll discuss the top of the bench, and move on to the skirt and vise installation. As I'm not exactly sure what I'm going to do for any of those, I'll just leave you with this tidbit for today.

Have a great day in the shop!

Tuesday, May 22, 2007

Saturday, May 19, 2007

Small Workbench #2: Using Domino to bore mortises for tressel base...

Yeehaw! I anticipated this step all day. I had originally planned to use Dowelmax to join these pieces because I was more comfy with the jig and this has to align perfect. I then though, phooey! I'll use Domino and give it a good test drive.

The first picture shows the Festool Domino fitted with the Trim stop. This fitting allows you to "center or off-set the Domino joiner on narrow work pieces for perfect positioning."

HA! If anyone can screw this up, I can! I defy a tool company to make a jig that I can't find a way to ignore the instructions and eventually misuse....

Well, as you can see in the background, I had to get the instructions out. I couldn't figure out how to put the trimstop on the Domino. After about 4 seconds of looking at a picture, banging me head into the headstock on my lathe in self disgust, I fit the trimstop on and centred the unit to the test piece that I had measured and marked, and made a test cut.

After making the first cut, I just stuffed each piece into the the trimstop and cut the remaining 15 mortises. Clarity of thought might have led me to take my time and measure each one to ensure that I was going to end up with the right alignment in the end, but trust tthe tool, I always say. Sometimes, I end up being the "tool."

They look okay, but time will tell. There is another essential step or two to see if I can pull this off. As you can see, I decided to put two (2) dominos in each joint just to really test the limits of measurement error or success.

Now, when I went to measure and mark where I wanted the ajoining mortises on the tressel base and top, the indexing pins on the Domino were too close to the edge. I tossed on the outrigger attachment and found to my horror that I was in the "in between zone." Crap! Well, just move where you want the mortises. Right? That would be too easy. Lets find another way to index. I started thinking, "What would Dowelmax do?"

I didn't really think that, but the indexing rod for Dowelmax was sitting on the bench and I just happened to pick it up.

I lined up the Domino on the first cut, set the indexing rod, and proceeded to cut the remaining 15 matching mortises in the tressel base and tops. This is NOT going to fit. No way, no how. But, I press on!

Just when I must be looking like a genius to everyone reading this, my humility knows no boundries. So I have therefore included a video of me trying to use the darn indexing rod. I mean, this is really Keystone Cops stuff. In my defence, however, if I held the Domino with my right hand, and the indexing bar with my left...even with the opposite side cross-over maneuver, then this entire process goes REALLY easy...I may remember that for next time...may.

Well, they look pretty good to me. They still have to fit though. You see, back in the beginning, I forgot to mention how I had chosen to make this EVEN MORE difficult. I could have milled the tressel base and legs to exact dimensions. Then just set the fence on Domino (hereafter affectionately named, Lucille (BB King Joke).) Instead I wanted a reveal on every leg. I'm going to make this so there is not a popsicle's chance in the Bayou of working....this involved some test cuts and measuring on some scrap...it took about 20 minutes to get things setup where I thought they were pretty good.

Well, so far so good, eh? (I'm Canadian)

I didn't get too excited, as anyone that has made a piece with slats or spindles knows, the big gal hasn't sung yet...I still have to lined up the ajoining piece of tressel top. I'm admittedly equally excited and nervous at this point.

I put glue on (more than the picture shows) and drove the pieces together with my handy dandy mallet and a piece of scrap wood. This little endeavour met with a knock on the shop door and a rather annoyed look from my wife...kids sleeping...banging...all that...yada yada yada...I'm on a role...I'll fix the damage to the upper two floors in a second.

Well, nobody was as shocked as I. They both fit. I tossed a couple of K-bodies on them and left the shop for the night to tell my imaginary friends of my exploits of precision and design...or blind assed luck...depends on how well you know me!

The project forges forward!

The first picture shows the Festool Domino fitted with the Trim stop. This fitting allows you to "center or off-set the Domino joiner on narrow work pieces for perfect positioning."

HA! If anyone can screw this up, I can! I defy a tool company to make a jig that I can't find a way to ignore the instructions and eventually misuse....

Well, as you can see in the background, I had to get the instructions out. I couldn't figure out how to put the trimstop on the Domino. After about 4 seconds of looking at a picture, banging me head into the headstock on my lathe in self disgust, I fit the trimstop on and centred the unit to the test piece that I had measured and marked, and made a test cut.

After making the first cut, I just stuffed each piece into the the trimstop and cut the remaining 15 mortises. Clarity of thought might have led me to take my time and measure each one to ensure that I was going to end up with the right alignment in the end, but trust tthe tool, I always say. Sometimes, I end up being the "tool."

They look okay, but time will tell. There is another essential step or two to see if I can pull this off. As you can see, I decided to put two (2) dominos in each joint just to really test the limits of measurement error or success.

Now, when I went to measure and mark where I wanted the ajoining mortises on the tressel base and top, the indexing pins on the Domino were too close to the edge. I tossed on the outrigger attachment and found to my horror that I was in the "in between zone." Crap! Well, just move where you want the mortises. Right? That would be too easy. Lets find another way to index. I started thinking, "What would Dowelmax do?"

I didn't really think that, but the indexing rod for Dowelmax was sitting on the bench and I just happened to pick it up.

I lined up the Domino on the first cut, set the indexing rod, and proceeded to cut the remaining 15 matching mortises in the tressel base and tops. This is NOT going to fit. No way, no how. But, I press on!

Just when I must be looking like a genius to everyone reading this, my humility knows no boundries. So I have therefore included a video of me trying to use the darn indexing rod. I mean, this is really Keystone Cops stuff. In my defence, however, if I held the Domino with my right hand, and the indexing bar with my left...even with the opposite side cross-over maneuver, then this entire process goes REALLY easy...I may remember that for next time...may.

Well, they look pretty good to me. They still have to fit though. You see, back in the beginning, I forgot to mention how I had chosen to make this EVEN MORE difficult. I could have milled the tressel base and legs to exact dimensions. Then just set the fence on Domino (hereafter affectionately named, Lucille (BB King Joke).) Instead I wanted a reveal on every leg. I'm going to make this so there is not a popsicle's chance in the Bayou of working....this involved some test cuts and measuring on some scrap...it took about 20 minutes to get things setup where I thought they were pretty good.

Well, so far so good, eh? (I'm Canadian)

I didn't get too excited, as anyone that has made a piece with slats or spindles knows, the big gal hasn't sung yet...I still have to lined up the ajoining piece of tressel top. I'm admittedly equally excited and nervous at this point.

I put glue on (more than the picture shows) and drove the pieces together with my handy dandy mallet and a piece of scrap wood. This little endeavour met with a knock on the shop door and a rather annoyed look from my wife...kids sleeping...banging...all that...yada yada yada...I'm on a role...I'll fix the damage to the upper two floors in a second.

Well, nobody was as shocked as I. They both fit. I tossed a couple of K-bodies on them and left the shop for the night to tell my imaginary friends of my exploits of precision and design...or blind assed luck...depends on how well you know me!

The project forges forward!

Thursday, May 17, 2007

Small Bench

I'm about to undertake a quick little project. An auxillary bench for my main workbench. I've been learning to cut the dovetail by practicing alot and watching some Rob Cosman videos. I've found that my bench is too short to comfortably do this. This little guy will have it's tressle base made of maple, but it's top will be less fancy. I'll probably just laminate a piece of oak plywood to a hunk of MDF and put an apron around it. I originally thought that I'd laminate a maple top for it, but I didn't feel like making this thing weigh 60 lbs. Anyway, I'm going to use the Domino for joinery and should be able to start this project this week. I have some S2S maple on the rack ready to go.

I'll have construction photos and possible a short video on the bench construction. construction photo's will be on my Picasaweb Album.

Cheers!

Tool Blog Updates

I've got some new videos on my Tool Blog showing a Festool MFT 1080 as a tablesaw outfeed. I also do a brief comparison of Dowelmax vs. the Festool Domino with a quick frame joint and edge joining. If you want to watch some poorly produced videos, take a peak!

Cheers!

Friday, May 11, 2007

Video Shop Tour

Hi Folks! There is a little contest over at Lumberjocks.com for video shop tours. I thought I'd make one up. I hope you enjoy it.

Cheers!

Tuesday, May 1, 2007

Entertainment Centre - Final

Well, it's done. Almost. The door glass still hasn't been cut. I commissioned it and it was supposed to be done yesterday. **shrug** It's installed in my parents basement. As a note of humour and curiosity, I compiled a list of the tools and fixtures I used to create it. I was almost embarassed as it's certainly more than the handsaw, hammer and glue that my grandfather used to create his kitchen cabinets. Regardless, here's the tool list.

I had quite alot of fun building this project. It's about the perfect size for me to knock off in a month or so of an hour here, hour there. There are no major mistakes and the thing is built like a tank...at least I think so.

The method of constructing it in parts, finishing them, then transporting to final destination before assembly, worked really well for me. There was no nut busting piece of furniture to sweat out of the shop, and I didn't need any help getting it into my parents basement.

As always, construction pics are in my Picasa Album for this project.

Thanks for looking!

I'm going to be finishing my first impressions of some Festool tools in the next couple of weeks. Sitting down in the shop is a new Domino, TS 55 and MFT 1080. I'll give them a test drive and see how things go. That info will be in my Tool Blog.

Cheers!

Subscribe to:

Comments (Atom)